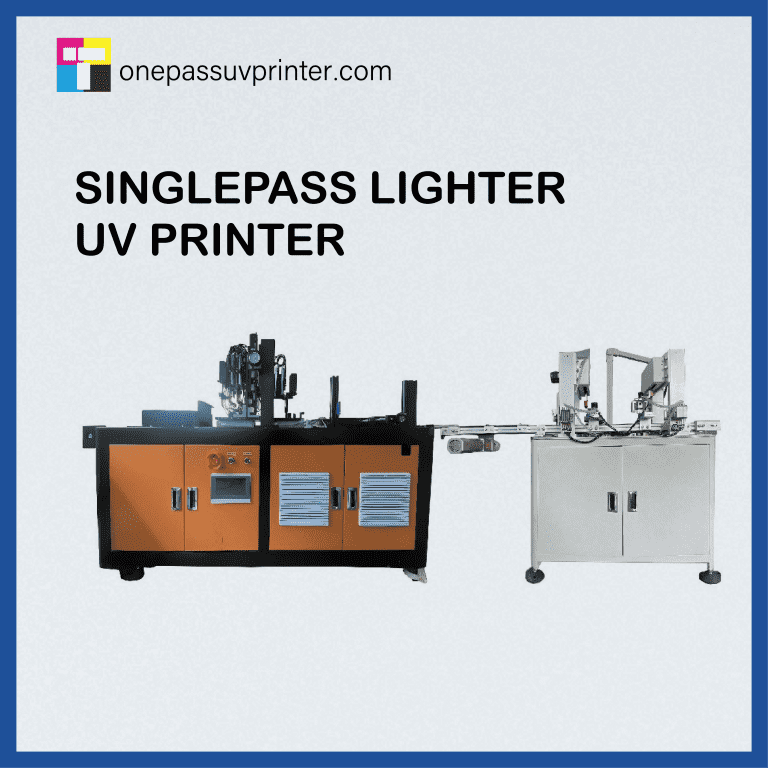

Packaging print domain is transforming rapidly due to novel one-pass UV equipment. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. Using UV curing to set inks instantly, single-pass UV removes extended drying cycles and repeat runs, cutting costs and turnaround.A central benefit is its capacity to render vibrant, lasting images across various substrates including plastic, metal, and cloth. Superior resolution in single-pass UV yields finely detailed graphics and text, suited for packaging, signs, and marketing collateral. Besides, its lower energy demands compared with older methods contribute to a reduced environmental footprint in production.

Packaging print domain is transforming rapidly due to novel one-pass UV equipment. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. Using UV curing to set inks instantly, single-pass UV removes extended drying cycles and repeat runs, cutting costs and turnaround.A central benefit is its capacity to render vibrant, lasting images across various substrates including plastic, metal, and cloth. Superior resolution in single-pass UV yields finely detailed graphics and text, suited for packaging, signs, and marketing collateral. Besides, its lower energy demands compared with older methods contribute to a reduced environmental footprint in production. Bringing in one-pass UV creates expanded potential for businesses to optimize their printing processes.

Bringing in one-pass UV creates expanded potential for businesses to optimize their printing processes. Single-Pass UV Trends

High-throughput digital printing persistently aims for efficiency. Historically this required several ink passes, increasing run times and misregistration risk. Still, the emergence of Single-Pass UV is shifting the market. With single-run UV curing, inks set instantly, offering remarkable enhancements in throughput and precision.Single-Pass UV produces vivid color with exceptional clarity, delivering unmatched detail and depth. This suits demanding uses like large-scale packaging, billboards, and promotional work where rapidity and impact matter. With continued progress, expect single-pass UV to produce further leaps enabling quicker, more versatile, and cost-effective output.

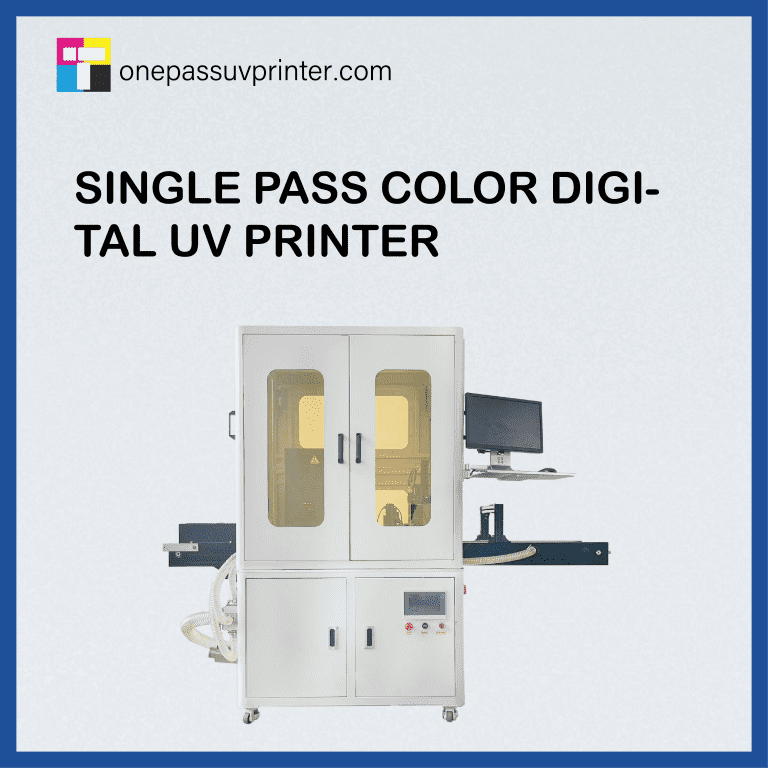

Single-Pass UV Printers: Redefining Productivity

In today’s print technology landscape, single-pass UV devices have become a disruptive innovation for speed, precision, and efficiency. Such machines use UV curing to set inks instantly, allowing extraordinary production speeds. Their single-pass multi-color output results in top-tier resolution and vivid color accuracy. From bespoke product printing to large-scale commercial runs, these machines serve varied use cases, enabling firms to address rising demand.Elevate Your Printing Process

Be prepared to be astonished by the single-pass UV printer — a robust solution elevating industry expectations. This inventive machine relies on UV light to cure inks instantly in one pass, achieving superior image quality and resolution.- Benefit from vivid color depth with crisp accuracy

- Accelerate output with fast production printing

- Extend creative potential with wide material compatibility

Accelerated UV Printing: Delivering Unmatched Efficiency

UV printing revolutionized graphic production by offering faster runs, higher precision, and striking color. Yet express UV printing heightens these benefits, delivering remarkable manufacturing efficiency. The tech leverages purpose-built printers that output high-res images extremely fast. With near-instant curing and minimal drying, speedy UV printing enhances workflows enabling easy completion of demanding jobs. The value of rapid UV printing reaches beyond efficiency to include durability and application range. It also offers exceptional print quality, durability, and a wide range of applications. From packaging and banners to labels, promos, and signage, high-speed UV is changing business workflows and enabling innovation, agility, and competitive advantage.

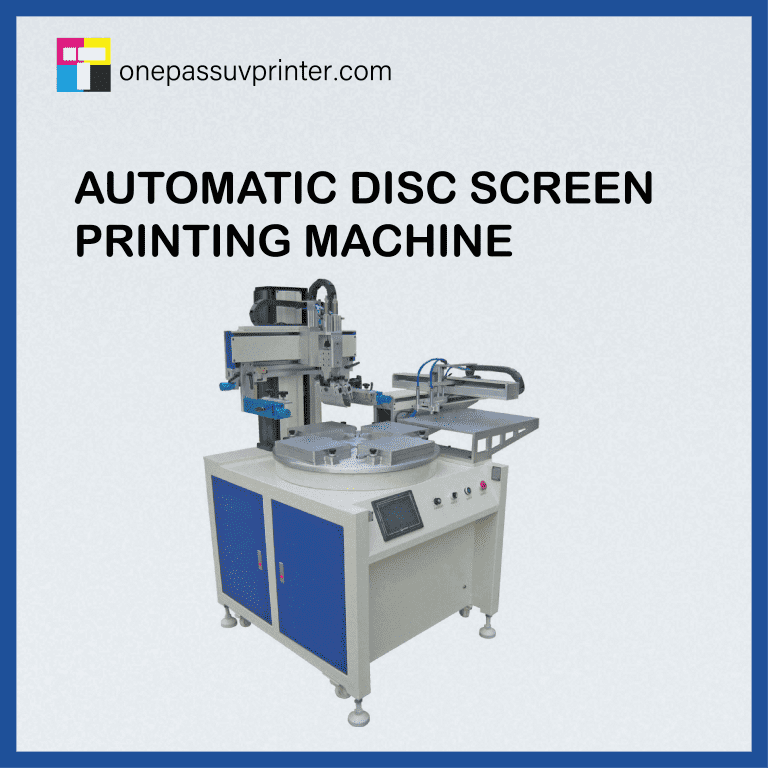

Single-Run Production: The Ultimate Solution for Fast Turnaround Times

In a time-driven market, speed is crucial. Regarding print, firms need systems delivering quick, effective output. This is where One-Pass Print plays a role. The system supports one-pass prints, eliminating repeat runs and reducing overall process time. One-Pass Print offers dramatically quicker turnaround times, recovering valuable time and capacity. As a result, businesses of all sizes can benefit from the advantages of One-Pass Print. From promotional pieces to critical documents, the tech enables timely printing without sacrificing quality.Ultraviolet Inspection: Bridging the Gap Between Speed and Accuracy

In current manufacturing contexts, efficiency is top priority. Manufacturers look for methods that deliver excellence without slowing production. Single-pass UV surfaces as a pioneering solution tying high-quality inspection to quick curing. This process uses immediate UV curing of inks and coatings to produce vivid durable finishes while shortening production time. Single-pass UV’s accuracy results in flawless goods meeting demanding quality norms. Benefits expand beyond improved speed and fidelity. Single-pass UV reduces unnecessary waste by cutting drying time, aiding environmental sustainability.- Furthermore, the broad applicability of single-pass UV spans packaging, printing, and electronics production.

Redefining Digital Printing with High-Speed UV

Printing continues to change under constant pressure for faster performance, finer precision, and novel technology. Fast UV technology has arisen as a key disruptor, marrying speed with precision and flexibility. UV printing relies on ultraviolet curing to set inks immediately, removing long dry cycles and expanding printer capabilities. Rapid cure allows very high print speeds, substantially lowering production time and increasing overall efficiency. In addition, UV inks are tough and resist fading, scratching, and water, making them suitable for various applications. From vibrant displays to durable product packaging, high-speed UV printing is redefining the way we print.- Pros

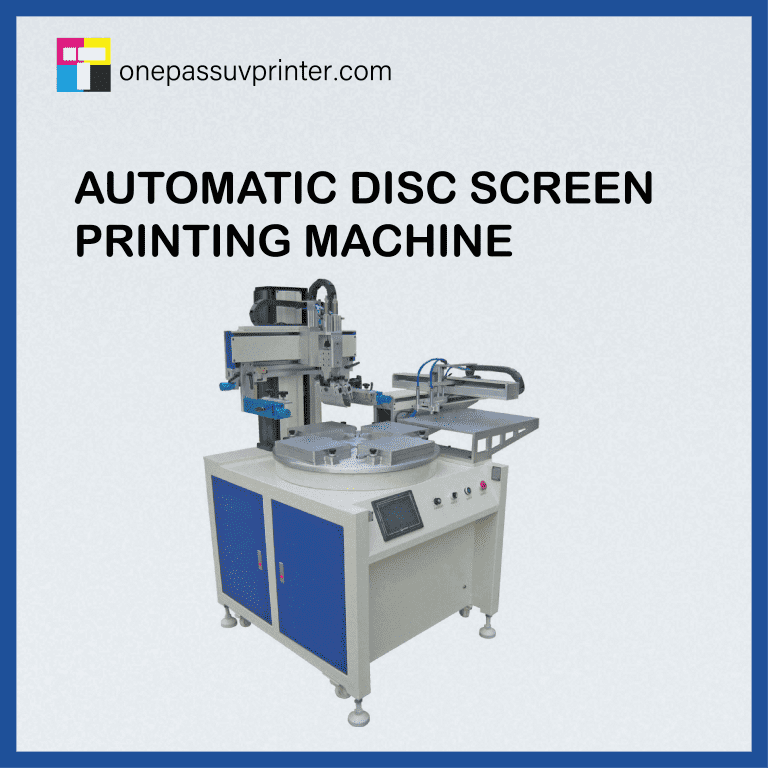

Quick Print Era: One-Pass UV Systems

Within rapid graphics and design markets, time holds great value. Clients expect speedy turnarounds and companies must produce high-quality prints quickly. This is where one-pass UV printers step in, offering a revolutionary solution for the modern printing industry. These modern machines employ UV inks which cure immediately in light, bypassing time-consuming drying steps. The payoff: immediate prints with bold colors and long-lasting finishes. Therefore, one-pass UV systems are being adopted across diverse industries. From retail, e-commerce, and marketing to photographic, fine-art, and manufacturing uses, businesses utilize instant printing. Applications include creating personalized products, producing custom signage, and generating eye-catching marketing materials. The benefits reach further than speed and process gains. Single-pass UV offers exceptional color matching, crisp resolution, and wide substrate support suited to demanding tasks. digital printer- Moreover, one-pass UV supports greener production by eliminating solvent use and VOCs.

- In conclusion, instant-print era has arrived: with speed, flexibility, and quality, one-pass UV printers are transforming printing and enabling a more efficient future.

Upgrade Workflow with Single-Pass UV

Simplify production workflow and access higher efficiency using a single-pass UV printer. This cutting-edge system prints vibrant high-resolution images on diverse substrates in one pass, obviating layered stages.- Secure extraordinary speed and decrease production time.

- Increase output via faster order processing.

- Capitalize on UV ink durability and precision for long-term vivid output.

The Benefits of Single-Pass UV in High-Impact Printing

Single-pass UV printing stands out as a transformative approach to high-impact print. Employing UV-induced instant curing, this method yields substantial benefits over traditional printing. Initially, single-pass UV offers superior image quality through intense colors and fine detail. Curing instantly removes drying delays, boosting productivity and shortening turnaround.- Moreover, the method creates hard-wearing prints that resist fading, scratching, and abrasion.

- Overall, the combination of high image quality, increased throughput, and durable output makes single-pass UV attractive for high-impact printing.