Digital print arena is transforming rapidly due to novel one-pass UV equipment. This advanced approach delivers high-volume production together with premium durability and clarity. By harnessing UV light to cure inks on contact, single-pass UV printing negates long drying periods and repeat passes, decreasing production cost and cycle time.A standout benefit is its capability to output lively, enduring prints across multiple substrate types, e.g., plastics, metals, fabrics. The high resolution capabilities of one-pass UV printing result in stunningly detailed images and text, making it ideal for applications such as packaging, signage, and promotional materials. Moreover, its eco-friendly profile reduces power consumption relative to legacy printing techniques, aiding sustainability efforts.

Digital print arena is transforming rapidly due to novel one-pass UV equipment. This advanced approach delivers high-volume production together with premium durability and clarity. By harnessing UV light to cure inks on contact, single-pass UV printing negates long drying periods and repeat passes, decreasing production cost and cycle time.A standout benefit is its capability to output lively, enduring prints across multiple substrate types, e.g., plastics, metals, fabrics. The high resolution capabilities of one-pass UV printing result in stunningly detailed images and text, making it ideal for applications such as packaging, signage, and promotional materials. Moreover, its eco-friendly profile reduces power consumption relative to legacy printing techniques, aiding sustainability efforts. Embedding single-pass UV into operations opens up additional options for businesses wanting better print outcomes.

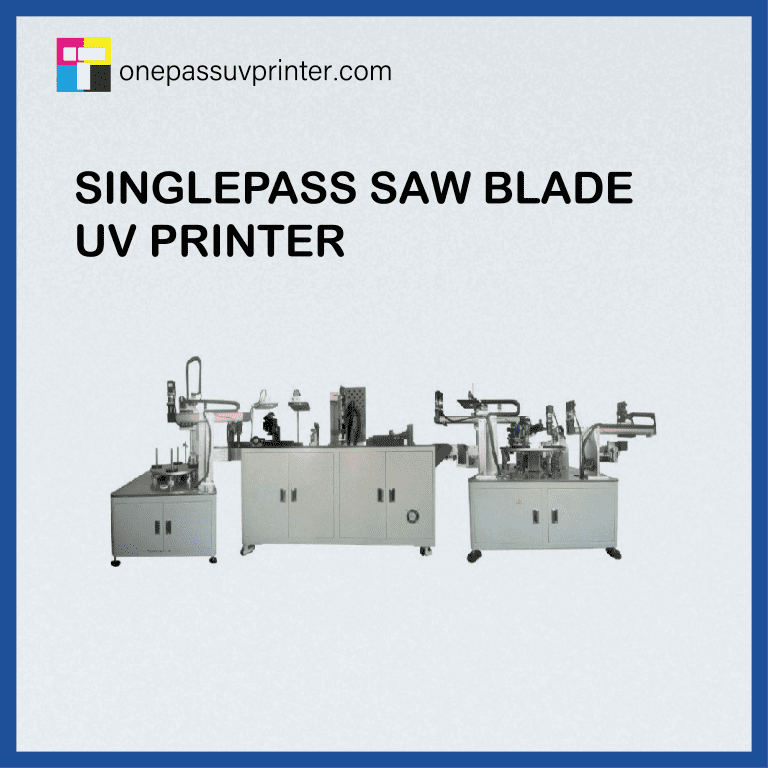

Embedding single-pass UV into operations opens up additional options for businesses wanting better print outcomes. Single-Pass UV Solutions

High-volume digital printing consistently targets efficiency. Previously this demanded multiple ink cycles, adding time and alignment challenges. However, Single-Pass UV’s introduction is transforming the sector. Using UV to cure inks in a single pass, the system delivers marked increases in throughput and exactness.Single-Pass UV produces vivid color with exceptional clarity, delivering unmatched detail and depth. This suits demanding uses like large-scale packaging, billboards, and promotional work where rapidity and impact matter. As advances continue, single-pass UV promises more revolutionary gains toward fast, flexible, and cost-efficient printing.

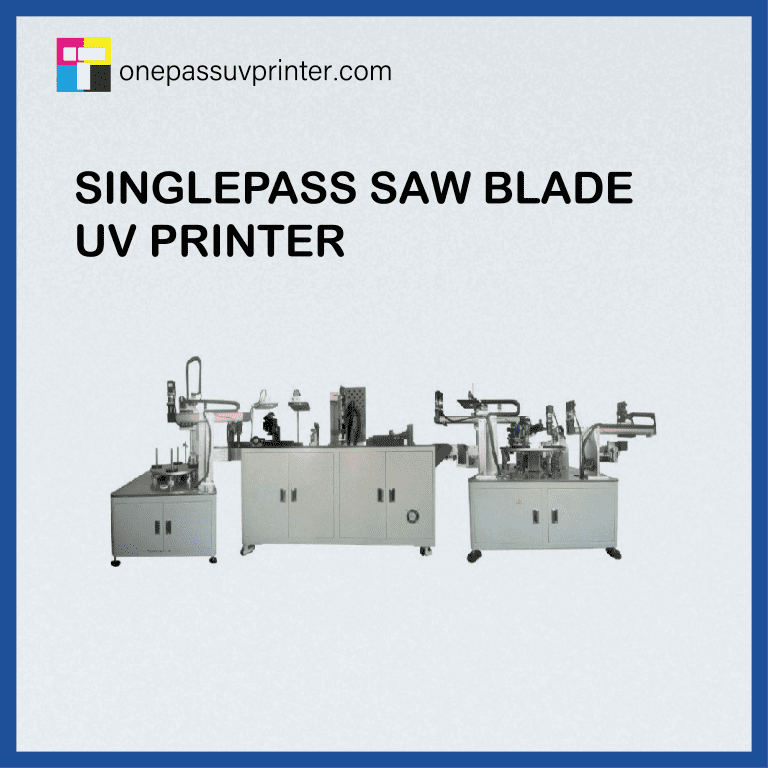

Single-Pass UV Printers: Next-Gen Throughput

Across print technology, single-pass UV units have quickly become essential for boosting speed, precision, and efficiency. These machines utilize UV curing to harden inks at speed, facilitating exceptional production levels. With the capacity to print several colors in one pass, these printers ensure great resolution and rich color delivery. From tailored product print to extensive commercial printing, these systems adapt to many uses, empowering businesses amid increasing demand.Reimagine Your Print Operations

Look forward to being impressed by the single-pass UV printer — a high-performance solution redefining standards. This ingenious machine utilizes ultraviolet light to cure inks in a single pass, achieving exceptional print quality and resolution.- Enjoy striking color fidelity with fine detail

- Accelerate output with fast production printing

- Explore diverse creative uses with multiple printable surfaces

High-Throughput UV Printing: Delivering Unmatched Efficiency

UV printing has modernized graphics production with faster cycles, accurate results, and vivid color. Yet express UV printing heightens these benefits, delivering remarkable manufacturing efficiency. This method uses tailored printers that generate high-resolution prints at impressive speeds. Through immediate curing and low dry times, high-speed UV streamlines production to handle even the most pressing orders. Advantages of high-speed UV printing span more than just efficiency improvements. It ensures premium print quality, dependable durability, and extensive application options. From packaging to banners, labels one pass printer to promotional displays, rapid UV printing modifies business processes to foster innovation and maintain an edge.

Single-Run Production: The Ultimate Solution for Fast Turnaround Times

Today’s fast-moving environment prioritizes speed. For printing, businesses require fast, efficient solutions. One-Pass Print fills that gap. It enables single-pass printing to avoid multiple runs and shorten total processing time. One-Pass Print secures much faster delivery times, freeing valuable time and resources. Therefore, organizations across sizes can leverage One-Pass Print advantages. From marketing content to important documents, it gives on-demand printing without losing quality.UV Inspection: Fast and Accurate

In contemporary production settings, efficiency is essential. Manufacturers insist on processes that combine superb quality with high speed. Single-Pass UV presents a novel solution that integrates precise inspection and rapid curing. The process harnesses UV light to cure inks and coatings immediately, giving durable vibrant finishes and shorter production cycles. The inherent accuracy of Single Pass UV ensures flawless products, meeting even the strictest quality standards. Advantages go further than just speed and quality. Single Pass UV reduces waste by eliminating the need for lengthy drying times, contributing to a more sustainable production process.- Moreover, single-pass UV’s universal utility fits industries from packaging and print to electronic device manufacturing.

Transforming Digital Printing Through High-Speed UV

The printing world evolves continuously, fueled by persistent calls for higher speed, improved precision, and innovation. High-speed UV appears as a pivotal innovation that blends speed, precision, and adaptability. UV printing relies on ultraviolet curing to set inks immediately, removing long dry cycles and expanding printer capabilities. Rapid curing supports accelerated print speeds, sharply decreasing production time and bolstering overall efficiency. Also, UV ink formulations are highly durable and resist fading, scratching, and water, fitting diverse applications. From striking displays to durable package printing, rapid UV printing transforms how prints are made.- Pluses

Instant Output Age: One-Pass UV Technology

Within rapid graphics and design markets, time holds great value. Clients expect speedy turnarounds and companies must produce high-quality prints quickly. This is where single-pass UV systems offer a game-changing solution for modern printing workflows. Advanced single-pass units use UV-based inks that cure on contact with light, removing drying delays. Outcome: instant prints featuring bright colors and enduring finishes. Consequently, single-pass UV printers are used in varied industrial applications. From retail and e-commerce through marketing, photography, art, and manufacturing, companies adopt instant printing solutions. Use cases range from individualized products to bespoke signage and striking promotional materials. The benefits reach further than speed and process gains. One-pass UV delivers precise color, excellent resolution, and compatibility with many substrates, ideal for demanding work.- Moreover, single-pass UV printing aids sustainability by avoiding solvents and VOC release.

- In short, instant prints are now mainstream; single-pass UV brings speed, adaptability, and quality that reconfigure printing for efficiency.

Improve Workflow Through Single-Pass UV

Tighten production process and realize greater efficiency via single-pass UV printing. This cutting-edge technology enables you to print vibrant, high-resolution images directly onto a variety of substrates in a single pass, eliminating the need for tedious layers.- Achieve remarkable speed and lower production timelines.

- Improve overall output with speedier turnaround.

- Use UV ink’s durable precision to secure long-lasting vibrant prints.

High-Impact Printing: The Advantages of Single-Pass UV

Single-pass UV printing has emerged as a revolutionary technology in the world of high-impact printing. Using UV light to instant-cure ink, this method provides major benefits compared to traditional processes. Firstly, single-pass UV printing provides unparalleled image quality due to its ability to produce highly vibrant colors and crisp details. By removing drying stages, the cure boosts productivity and speeds turnaround times.- Additionally, single-pass UV yields durable prints resistant to fade, scratch, and abrasion.

- To summarize, the blend of top image quality, higher productivity, and lasting durability makes single-pass UV ideal for high-impact printing needs.